Project Description

In collaboration with A Tiny Home for Good, a local Syracuse organization working to end homelessness. A Tiny Home for Good builds homes across Syracuse and is seeking a bed frame that they can manufacture in-house to replace off-the-shelf options.

How can we design a bed frame that ...

Costs ~200$

Made from common materials found in home improvement stores

Can be built by volunteers with little fabrication skill

Includes storage

Easily assembled

Four tiny homes developed in partnership with National Grid

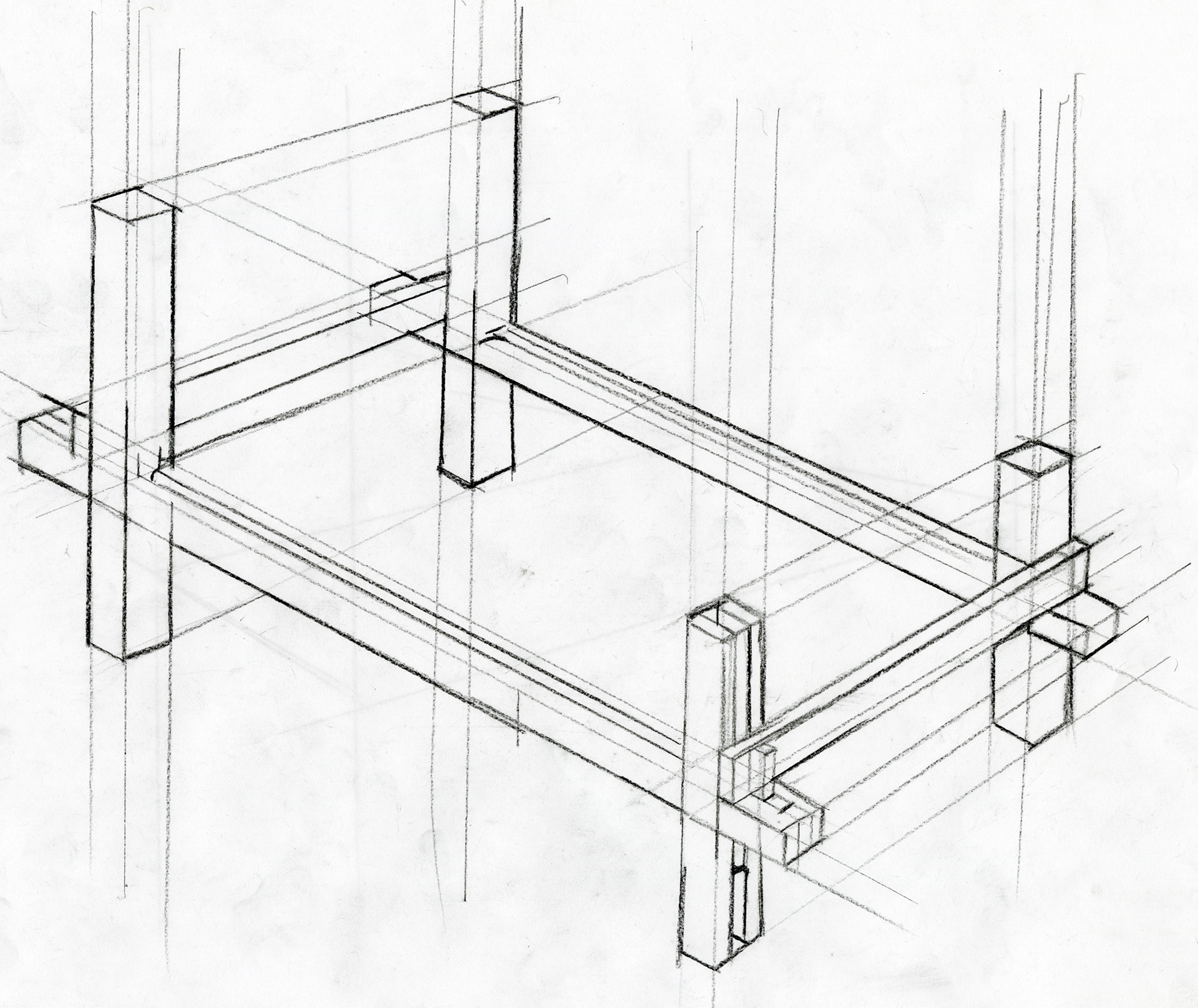

Ideation

Design Direction

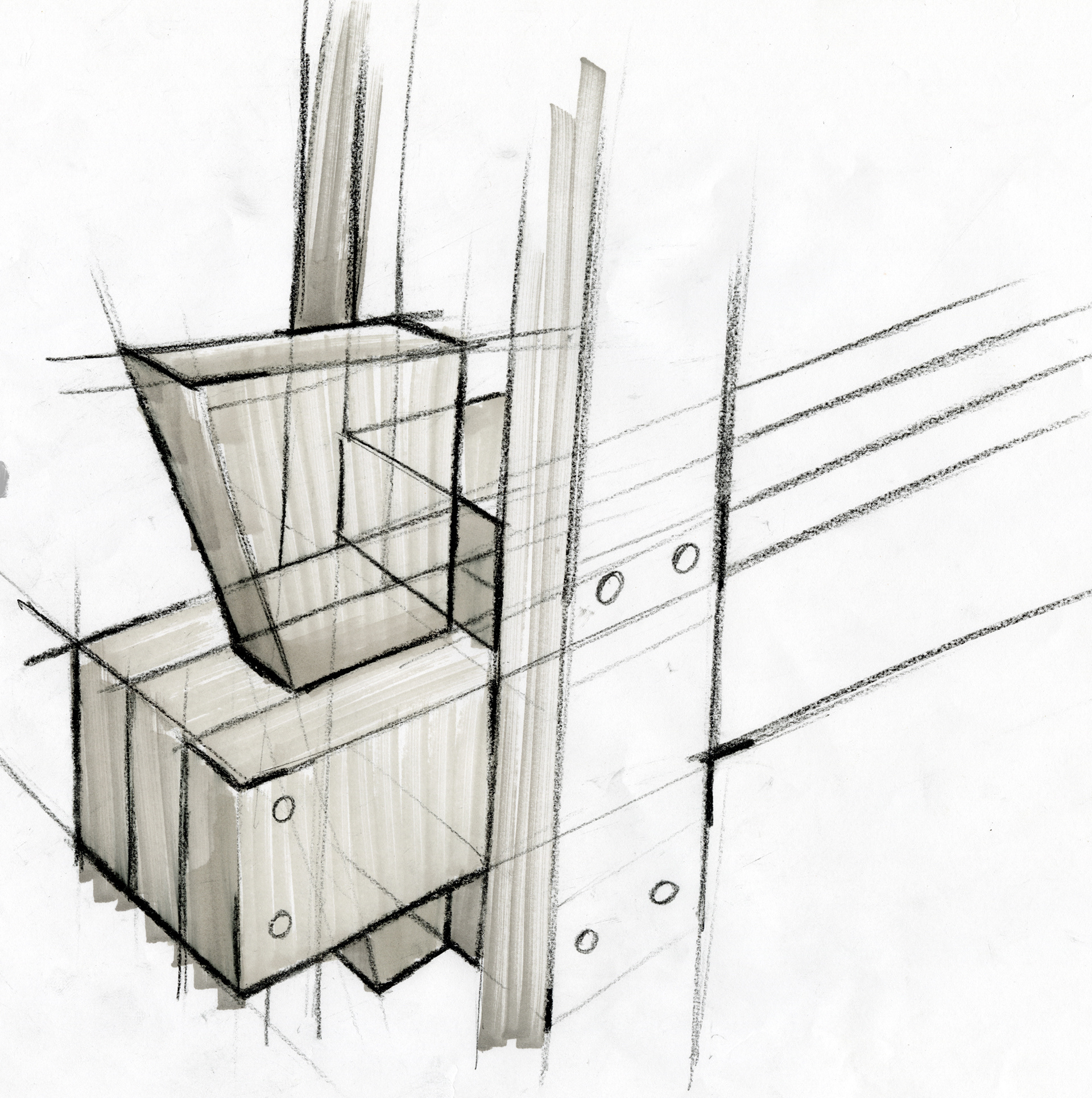

Most cheaply made furniture fails at critical joints. These joints are often made from fasteners and particle board, which, with regular use, will not last more than 10 years.

Wooden tenon joints have been used for thousands of years and are very durable. How can we create a simple version of this joint using limited tools?

Japanese wedged tenon carpentry

Dougong Bracket System Zhou Dynasty (around 1046–256 BCE)

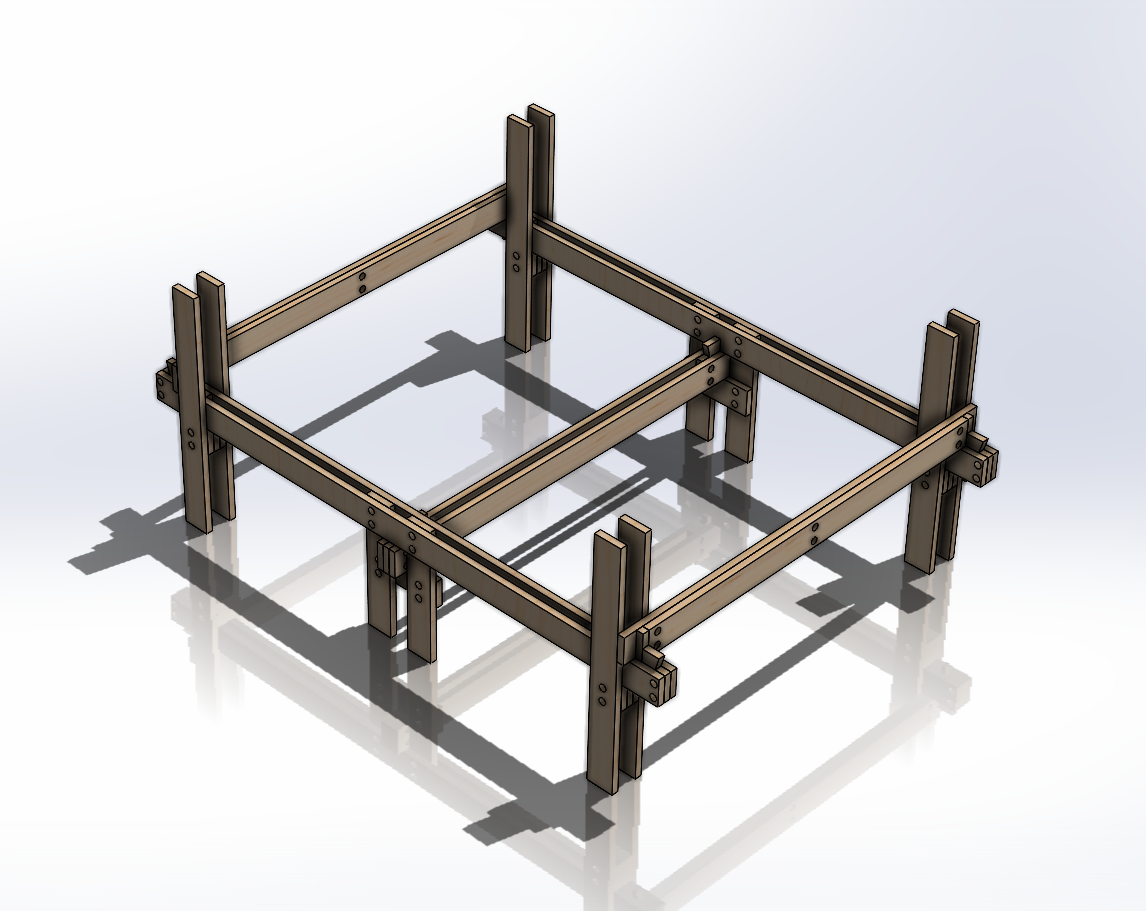

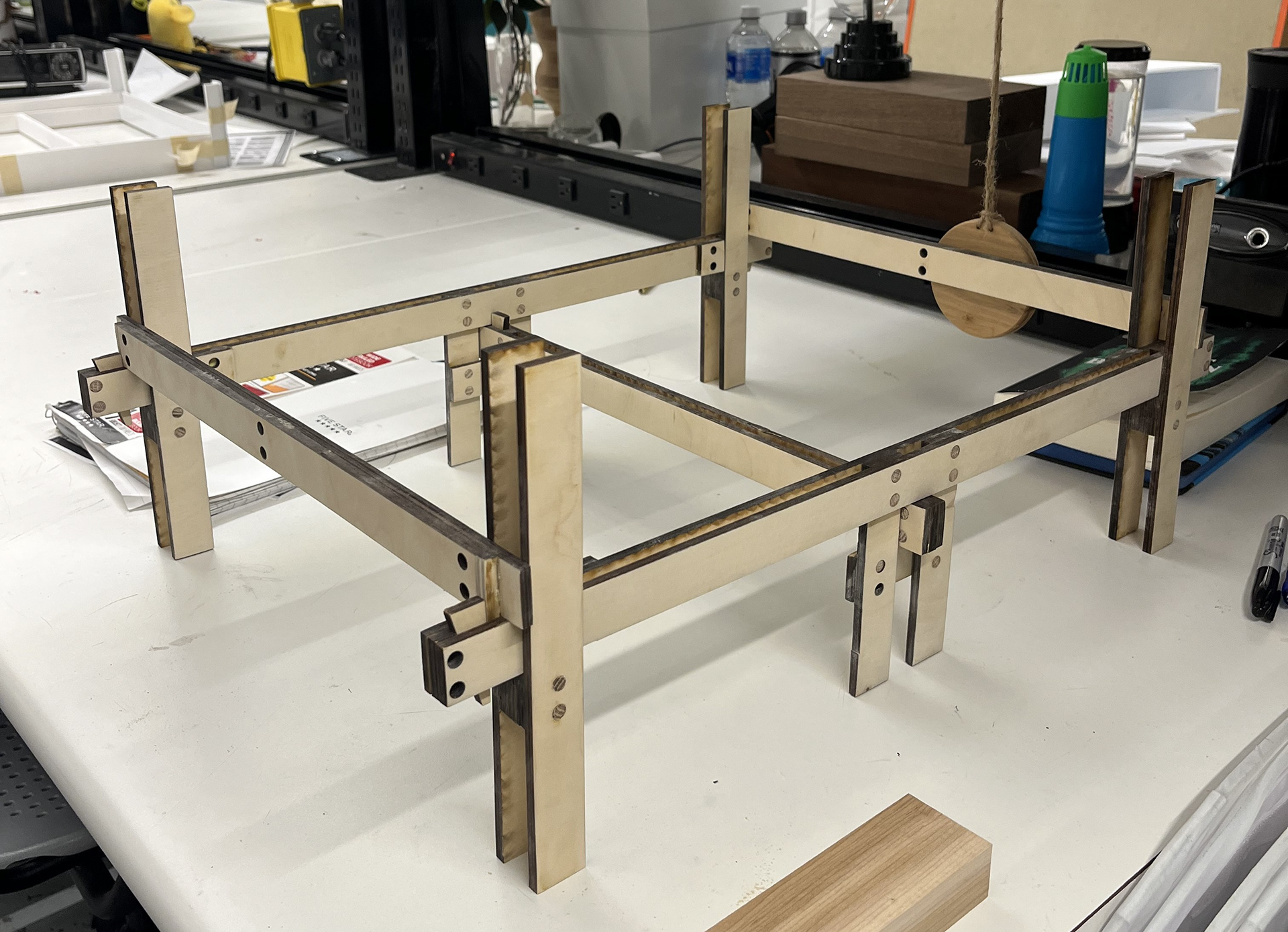

Solution

A construction made from stacked wooden pieces screwed together

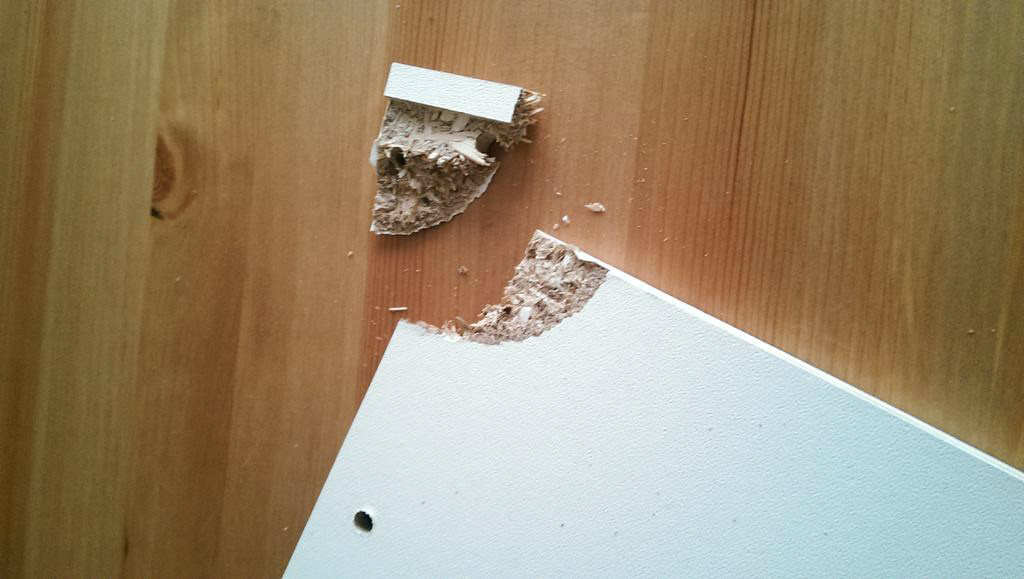

Quarter sized mockett

Construction

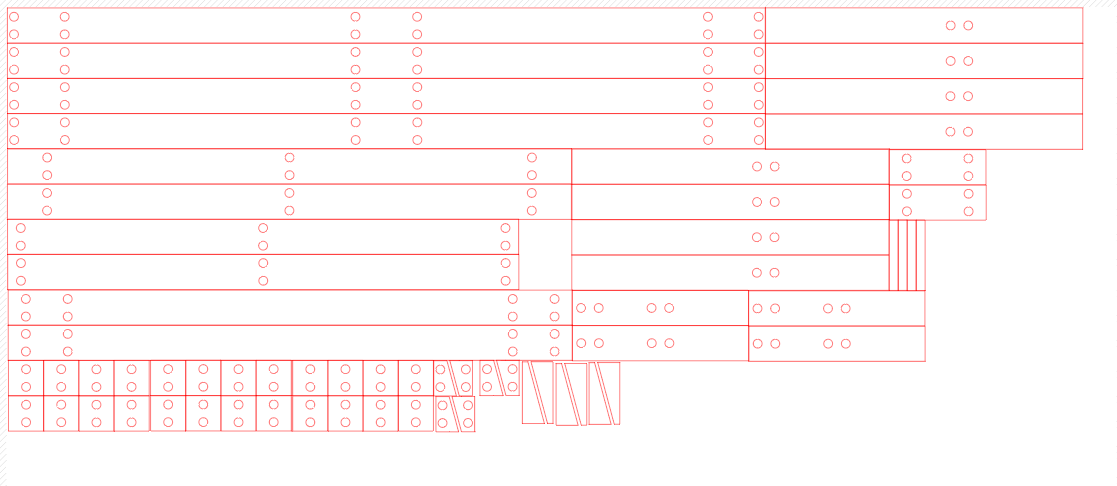

All pieces of the wedge bed are the same width, making fabrication simple. Wedges can be cut from scrap on the miter saw. Joints are assembled with wood screws. Storage is hung from the frame using soft storage cubbies - outsourced at any major box store. Can be assembled with just a hammer to secure wedges.

Tools Needed

Table saw

Miter saw

Hand drill

Cost - 170$

Roughly 1.5 sheets of plywood - $100

8 yards of canvas for the sling bed version - $60

Slats for classic bed - $65

Soft hanging storage - $10